Plastics are very good For many things, but they last a long time. Entropic is the set that jumps to the rescue. Enzymes They can be added to plastics at the beginning of their life cycle before they are converted into products. The company’s additives have tested proof-of-concepts and are looking to improve how plastics are made and disposed of.

Entropic additions Biodegradation of the most commonly used plastics in conventional commercial composting. Enzymes are usually added to pellets or powders used in plastic production. This gives plastics new, biodegradable capabilities without changing the manufacturing processes used to create plastic products. At the end of the life cycle, the products can be dissolved into their component parts when it is time to dispose of the material.

Aaron Hall, Entropic CEO, and Jolene Mattson, the company’s process engineer. Image Credits: Entropic materials.

The problem with current plastic disposal methods is that although plastic materials can decompose, nature takes them in from the outside and it takes a very long time. In an innovation from Entropic, at the Startup Battlefield at TechCrunch Disrupt 2022, additives are added to plastic raw materials, meaning the materials dissolve through a process called depolymerization. Basically, the polymer chains are reduced to monomers, which can be taken care of by natural normal decomposition processes.

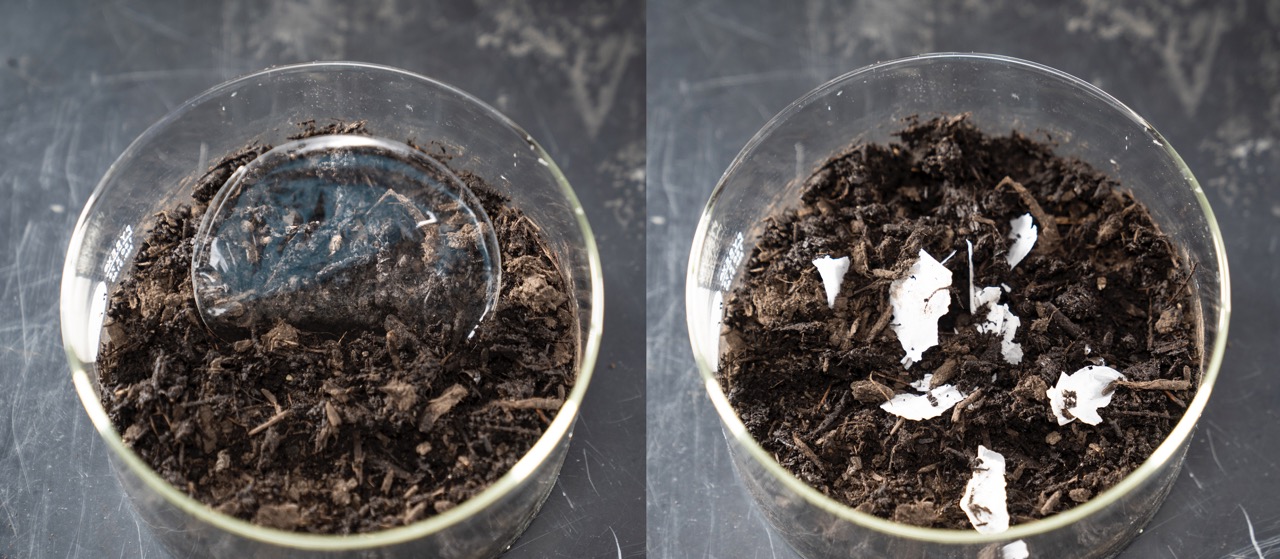

The company claims that when the plastics are exposed to water and relatively low temperatures (40ºC/104ºF), PLA and PCL plastics can degrade 98% faster if treated with additives. At an industrial level (for example, when plastics are cut or left out of normal manufacturing processes), a bath of water and heat can break down the plastic in less than 48 hours, and then it can be processed further. For post-consumer plastics, those same conditions occur naturally in commercial composting.

“Enzymes work with heat and water, not one or the other. We need both. And that’s important because if it was just the temperature, you wouldn’t be able to put it on a truck or in a warehouse in Arizona or Houston in the summer,” explained Aaron Hall, CEO and founder of Intropic. “If it’s just water, when it’s wet, you have things that suddenly melt or degrade. For now, we need both, but in the future, there are angles we can explore to create more control handles, which is really exciting.

Because the additives are added before manufacturers begin to shape the products, the potential uses are vast, the company told me, and because the manufacturing process itself doesn’t change, it could, in theory, spread quickly.

“We’re developing enzyme additives that can go into plastic and allow it to self-destruct. There are a lot of different application areas that are relevant,” says Hall. There’s plastic too, right? Think about all the packaging our tech comes in. The plastic our headphones come in, all the little sleeves, wrappings, etc.

Undegraded PLA (polylactic acid) plastic film is shown on the left, with biodegradable PLA fragments, on the right. Image Credits: Adam Lau / Berkeley Engineering

The company is still in its early stages, but is making very exciting progress. He completed proof-of-concept work and published a few papers in academic papers to demonstrate that the technology worked. Entropic is now working to scale up its production to the kilogram scale.

“We’re not tied to that number, but for example, let’s say we use 1% additives. That means one kilo of extra product can be the equivalent of 100 kilos of finished product,” Hall explains. “That’s more than enough to do testing and validation for the first stages. From there.” We want to get up and find partners.

The company is particularly focused on making the product work in large quantities, putting its energy to good use, and addressing plastic issues as much as possible.

“The way we want to formulate it is we’re doing this ‘master batch.’ It’s going to be a powder or a pellet depending on what our partners want. We can add it at the beginning, which means we can go into all kinds of products,” says Hal. It can be anything from injection molding, to roll-to-roll and plastics manufacturing. That’s, ultimately, what’s really cool about this addition: that’s how the process flow naturally works, which means it’s easy to integrate with multiple channels.

Image Credits: TechCruch

The company is very careful when making blanket claims about its effectiveness, explaining that the additives need to be activated by heat and water for rapid breakdown. I asked if it would be beneficial to have these plastic additives, even if the final product ends up in landfills, for example.

“As a PhD-trained scientist, I’m careful to make claims, but these enzymes are what they contain. can Even in a landfill environment with less favorable conditions, they lead to very rapid degradation. That’s certainly possible, but it’s something we want to confirm before making any strong claims about it. Having said that, it’s fun to entertain that idea, and there’s absolutely no reason to think it won’t work.

What impressed me the most about talking to the Entropic team is that they see themselves as part of a larger, more comprehensive solution to the plastics problem. The group spoke enthusiastically about other innovations in the materials space, particularly new, large-scale polymers and new materials that have been discovered.

“There’s been a lot of investment and excitement over the last few years in trying to explore these new directions. We’re part of that, but we’re approaching it from a different angle,” concludes Hall. We are seeing new materials made from different compounds with different chemistry from other players. I am very pleased with those and look forward to seeing those on the market. Similarly, they faced the problem of scale and integration.