The coming wave of satellite constellations all need power, but space-based solar panels are extremely expensive and difficult to manufacture. Solstial is poised to change that, with space-level panels made using inexpensive and scalable processes, and has raised just $10 million to take the technology from the lab to orbit.

The company, formerly known as Rager Solar, is based on years of academic research at Arizona State University to achieve space-level cell performance with materials and methods used for terrestrial solar panels.

When TechCrunch last contacted Solstial, the hollow solar cell was in the prototype stage, demonstrating that the hollow solar cell can withstand the harsh environment of space, despite being 1/10th the size of standard “III/IV” category panels.

“This is really the basis of our product, the solar cell that is not afraid of radiation; CEO and co-founder Stanislaw Herasimenka said that it has this special feature that cures their cells at a temperature of 80 degrees Celsius, which removes defects caused by radiation.

“But people don’t buy bare solar cells,” he continued.

Although the cells themselves work as advertised, no one wants to assemble them into panels. Solstial must ensure that not only its proprietary cells, but also its interconnects, ultra-thin silicon wafers and other components can survive in orbit for 10 years.

That means many tests are in order. Fortunately, the money and many potential customers have come to support the company’s efforts to displace expensive space panels — because there’s no way to build enough of them to support the next growing number of satellites. decade.

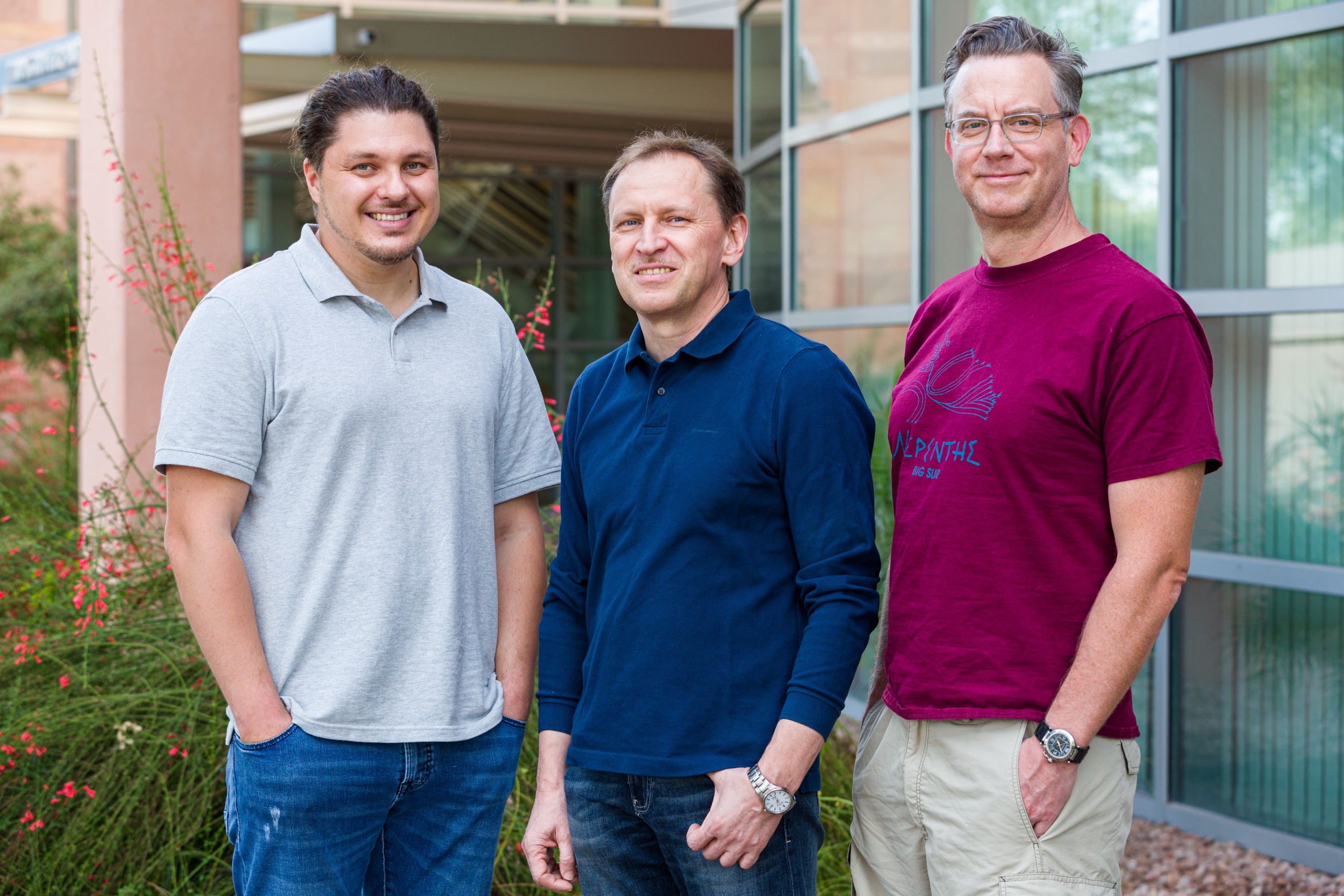

Technicians test a solar cell in the Solstial Lab.

Although the goal is 10 years in space, trying for that long is of course impossible. So whole panel assemblies are being subjected to accelerated stress testing, they’re exposed to more intense and different radiation than what’s normally seen there, as well as rapid temperature changes and things like that. This is a common thing in space work – it’s not like you can go to the moon to test the things you need to go to the moon, so do your best to simulate it on Earth.

“Our customers want to help us achieve flight heritage; we’ve provided a lot of small solar panels for demo flights, and we expect more next year,” said Herasimenko. This is in addition to stress testing and working on the manufacturing process: “Our customers want us to be able to mass-produce this thing, to move our technology from pilot production to mass production.”

Mass production is on the roadmap for about two years from now, during which time the company hopes to build tens of thousands of panels and deliver future constellations and larger installations.

It won’t be cheap, which is why Herasimenka told me a year ago that the seed round would close in a few months, instead it would take a year and double. “We’ve been advised that we need more money, and given the scope of what we’re doing, I agree with that. “It’s serious technology, it’s just the beginning, and we need to do more validation work,” he said of the delayed addition.

The new round was led by Airbus Ventures with participation from AEI HorizonX, GPVC, Stellar Ventures, Industrious

Venture and others. Solstial has previously raised about $2.5 million in SBIR awards, but to prove the theory, not to scale the company.

Founders of Solstial

Although they were just starting out, Herasimenka was confident they would be the main supplier of solar panels for the next generation of spacecraft, but they wanted to branch out and become a wider energy supplier – hence the name change from Reger Solar. Solstial. “It’s not that we hate the name, but we wanted one that better reflected our ambition to be a solar powerhouse in the space company. “We don’t want to remain a boring solar panel manufacturer forever, so we want a name that grows with us as a brand,” he said.

It could be at least two years before the first batch rolls off the production line, but Solstial is already eyeing that horizon. A communications satellite may last 8-10 years, but what about the larger craft in high orbits? What about large lunar mining operations? They welcome a space-intensive solar solution that won’t break the bank, but should last 20 years or more. That’s the next strategic step for Solstial, but first it needs to get the original product out the door.